Client: Medical Device Company

Topic: PEEK Optima Usage

The CHALLENGE

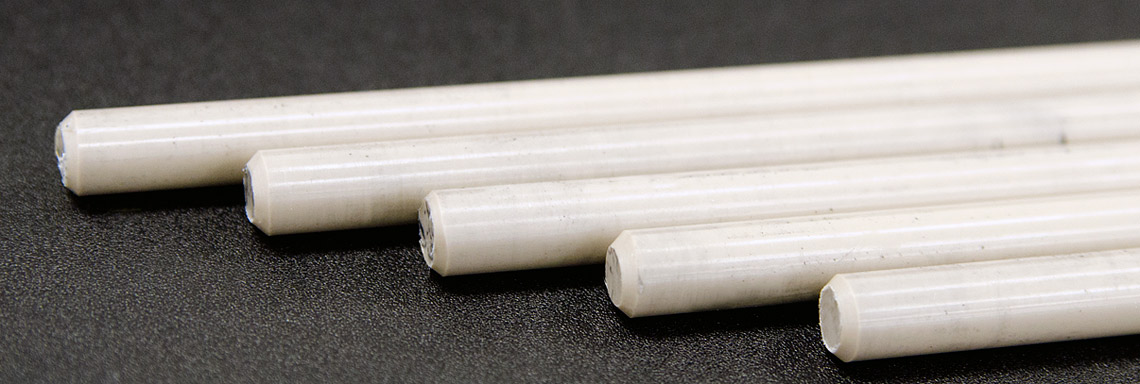

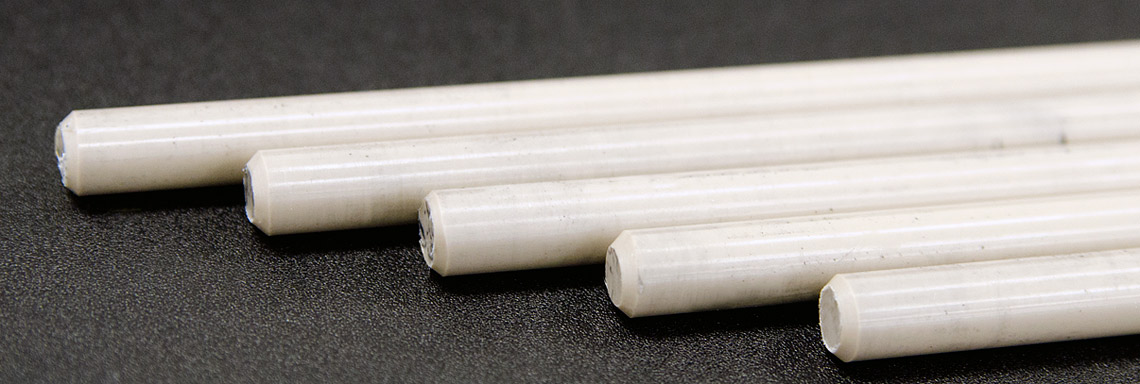

The customer supplied material which is PEEK Optima; an implantable PEEK comes in 36 inch lengths and costs around $1500 per yard. The process for many of the components that run through our Swiss machines leaves a 7-10 inch remnant which in turn creates about a quarter of each Rod of material into unusable material. PEEK may be recycled; however, since it is used for high value applications, recycled PEEK may not be used for the same applications as virgin PEEK.

The SOLUTION

Challenge Machine created an adapter rod to attach to each remnant, this created an increase in useable material and brought the remnant down to 1.5” instead of the 7-10 inch remnant. This brought down the material cost for the customer and allowed us to gain more parts per rod of material.

The RESULT

Challenge Machine had been assigned to bring down the total cost per item by using the current material more efficiently. The Swiss turning machine used by Challenge Machine is precise, but did not maximize the materials. A full design overhaul would have been too costly, so the best solution was to bring down the leftover remnant to an absolute minimum. This was achieved by creating and attaching an adapter to the end of the working material. By doing this, Challenge Machine was able to drastically decrease the amount of waste material and increase the output and efficiency of the current product.

Top